My previous post in this series ended with the group heading from St. Louis to Belle, Missouri to the site of the inaugural Kingsford Invitational barbecue competition. Not only were we about to be spectators to an incredible competition, but we'd also get to tour the largest Kingsford charcoal plant. As I said earlier, dudes love to see how things are made, so I was really looking forward to it.

Belle is a very small town located about two and a half hours southwest of St. Louis, and the drive has the palpable feel of midwest Americana. I spent my teen years in Columbia, which is smack dab between St. Louis and Kansas City, but it had been nearly 20 years since I'd been on the ground in this area of the country. What is known by some as "flyover country" was freshly familiar to me, and I enjoyed the trip.

The weather, minus the considerable wind, was just about as perfect as one could expect for early November in central Missouri. We enjoyed wall-to-wall sunshine with temperatures in the low 70's. The setting of the plant is not at all what I expected. It's in a what looks like a small valley that's surrounded by gently rolling hills, and at this time of year, trees still clad in multicolored leaves.

We walked to the plant and the first thing that catches your eye, other than the unexpected size of the complex, is the giant mound of what looks like dirt from a distance.

We went into the welcome area, donned our protective gear and, after a short safety briefing, we headed out to start the tour. We were split into several small groups and each was assigned a tour guide. Fortunately, my group had the plant manager, Steve Miller (no relation) as our guide. He was very friendly and more than eager to answer any and all of our questions.

Our first stop was that apparent dirt mound. It's actually an incredibly large pile of sawdust and wood that's recycled from various sources. How big? Well this plant produces something like seven million pounds of charcoal per day, and it takes eight pounds of raw wood to make one pound of what becomes the wood char from which the briquets are made. A little quick math tells you that this plant consumes about 56 million pounds of wood per day.

The wood (mostly oak, and some hickory) is trucked in and dumped. Then the dozer driver constantly mixes the wood so that the moisture level and age are as evenly distributed as possible. The dozer then pushes the wood into a huge chute that leads to what was described by Steve as a 200-horsepower garbage disposal. That machine chews up the wood and spits it out in a fairly uniform size onto the conveyor that feeds the plant.

Next the wood is fed into huge dryers that reduce the percentage of moisture in the wood from about 30 percent down to about five percent.

The dried wood then heads to the huge multi-stage oven, called a retort, that bakes the wood in an oxygen-starved environment at about 1000 degrees. The result is the wood char (black stuff) that makes up the bulk of each briquet.

What struck me as we walked past the retort was the absolute absence of any smell of anything burning. In fact, other than the smell of the wood pile, this plant has no smell.

When I asked Steve about that he pointed to the top of the stack on the right of the picture above and said, "See that? That's all the smoke that comes off of this plant." He went on to say that their retort is the most advanced in the world and that the emissions from this plant are incredibly low. Additionally, most of the energy used in the plant is recycled on-site.

The char is then mixed with a handful of other ingredients and is molded into the familiar briquet shape.

At this point the briquets have the consistency of a baked brownie. Steve handed each of us one and they were barely warm and easily broken apart by hand. The excess around the edges of each briquet is shaken off and recycled.

The briquets are then spread about a foot thick onto a huge conveyor which takes them through a gigantic dryer.

Hot air is forced through them from top and bottom and they emerge as the product that we know.

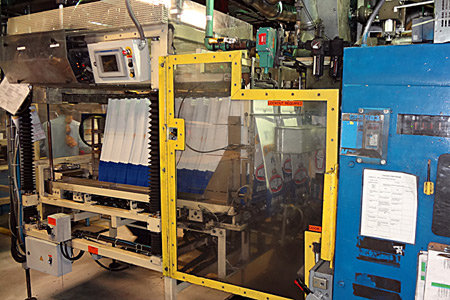

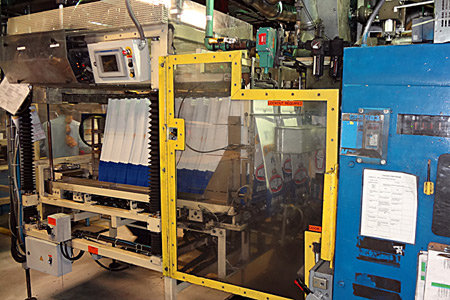

The product then heads to the bagging line.

The bags are blown open with air and filled.

Then they're sealed.

Next they head to the machine that automatically places the bags on pallets.

Finally, each pallet is robotically wrapped in plastic and placed for the forklift driver to take it to the warehouse.

Oh, and the warehouse is incredibly large. I think Steve said that it is 200,000 square feet.

As you can see, the pallets are stacked six high. Steve said that during the winter months that they work to fill the warehouse in preparation for the kick-off of grilling season (Memorial Day).

I can't thank the folks at the Kingsford plant in Belle enough for their hospitality and for the incredible tour. Steve was a great tour guide, and I could tell that he takes great pride in his crew and his plant. The place was incredibly clean for a charcoal plant. Oh, and it struck me that along the tour Steve stopped and thanked every worker that we encountered for coming in that day. It was the opening day of deer season, and the folks working that day volunteered to work. That kind of leadership is sadly rare these days.

In the next installment of this series I'll cover the Kingsford Invitational competition itself.

Related posts:

Kingsford Invitational - Part One

Kingsford Invitational - Part Two

The weather, minus the considerable wind, was just about as perfect as one could expect for early November in central Missouri. We enjoyed wall-to-wall sunshine with temperatures in the low 70's. The setting of the plant is not at all what I expected. It's in a what looks like a small valley that's surrounded by gently rolling hills, and at this time of year, trees still clad in multicolored leaves.

We walked to the plant and the first thing that catches your eye, other than the unexpected size of the complex, is the giant mound of what looks like dirt from a distance.

We went into the welcome area, donned our protective gear and, after a short safety briefing, we headed out to start the tour. We were split into several small groups and each was assigned a tour guide. Fortunately, my group had the plant manager, Steve Miller (no relation) as our guide. He was very friendly and more than eager to answer any and all of our questions.

Our first stop was that apparent dirt mound. It's actually an incredibly large pile of sawdust and wood that's recycled from various sources. How big? Well this plant produces something like seven million pounds of charcoal per day, and it takes eight pounds of raw wood to make one pound of what becomes the wood char from which the briquets are made. A little quick math tells you that this plant consumes about 56 million pounds of wood per day.

The wood (mostly oak, and some hickory) is trucked in and dumped. Then the dozer driver constantly mixes the wood so that the moisture level and age are as evenly distributed as possible. The dozer then pushes the wood into a huge chute that leads to what was described by Steve as a 200-horsepower garbage disposal. That machine chews up the wood and spits it out in a fairly uniform size onto the conveyor that feeds the plant.

Next the wood is fed into huge dryers that reduce the percentage of moisture in the wood from about 30 percent down to about five percent.

The dried wood then heads to the huge multi-stage oven, called a retort, that bakes the wood in an oxygen-starved environment at about 1000 degrees. The result is the wood char (black stuff) that makes up the bulk of each briquet.

What struck me as we walked past the retort was the absolute absence of any smell of anything burning. In fact, other than the smell of the wood pile, this plant has no smell.

When I asked Steve about that he pointed to the top of the stack on the right of the picture above and said, "See that? That's all the smoke that comes off of this plant." He went on to say that their retort is the most advanced in the world and that the emissions from this plant are incredibly low. Additionally, most of the energy used in the plant is recycled on-site.

The char is then mixed with a handful of other ingredients and is molded into the familiar briquet shape.

At this point the briquets have the consistency of a baked brownie. Steve handed each of us one and they were barely warm and easily broken apart by hand. The excess around the edges of each briquet is shaken off and recycled.

The briquets are then spread about a foot thick onto a huge conveyor which takes them through a gigantic dryer.

Hot air is forced through them from top and bottom and they emerge as the product that we know.

The product then heads to the bagging line.

The bags are blown open with air and filled.

Then they're sealed.

Next they head to the machine that automatically places the bags on pallets.

Finally, each pallet is robotically wrapped in plastic and placed for the forklift driver to take it to the warehouse.

Oh, and the warehouse is incredibly large. I think Steve said that it is 200,000 square feet.

As you can see, the pallets are stacked six high. Steve said that during the winter months that they work to fill the warehouse in preparation for the kick-off of grilling season (Memorial Day).

I can't thank the folks at the Kingsford plant in Belle enough for their hospitality and for the incredible tour. Steve was a great tour guide, and I could tell that he takes great pride in his crew and his plant. The place was incredibly clean for a charcoal plant. Oh, and it struck me that along the tour Steve stopped and thanked every worker that we encountered for coming in that day. It was the opening day of deer season, and the folks working that day volunteered to work. That kind of leadership is sadly rare these days.

In the next installment of this series I'll cover the Kingsford Invitational competition itself.

Related posts:

Kingsford Invitational - Part One

Kingsford Invitational - Part Two

Post a Comment

Note: Comments containing profanity or blatant promotion/spam will not be published